Industrial Valves

Rivulet Industries LLP. is a trusted Manufacturer and Exporter of high-quality Industrial Valves, engineered to meet stringent industry standards. Based in Mumbai, India, we specialize in precision-engineered valves that provide exceptional control, durability, and reliability for various industrial applications.

Our extensive product range includes Butterfly Valves, Ball Valves, Gate Valves, Globe Valves, Pinch Valves, Diaphragm Valves, and more, available in different sizes, pressure ratings, and specifications to suit diverse industrial requirements. We manufacture valves in compliance with DIN, ASTM, ASME, BS, and all International Standards, ensuring superior performance, corrosion resistance, and longevity.

Manufactured using high-grade materials, our industrial valves are designed for leak-proof sealing, high-pressure endurance, and smooth operation. We supply valves in a wide range of materials, including Stainless Steel, Carbon Steel, Alloy Steel, and specialty alloys. Each product undergoes stringent quality checks and non-destructive testing (NDT) to ensure precision and reliability.

Our industrial valves are widely used in industries such as Oil & Gas, Petrochemicals, Power Plants, Water Treatment, Chemical Processing, Shipbuilding, and Heavy Engineering. Designed to perform under high-pressure, high-temperature, and corrosive environments, our valves provide optimal flow control, safety, and durability.

At Rivulet Industries LLP., we offer customization options in terms of sizes, pressure ratings, end connections, and materials to meet specific project requirements. Our industrial valves are available in the following range:

Available Grades of Industrial Valves

| Alloy Type | Available Grades |

|---|---|

| Duplex Steel | Alloy-2205, Alloy-2304, Alloy-329 |

| Super Duplex Steel | Alloy-2507 / F53, Alloy-2507 / F55, Alloy-255 |

| Nickel Alloys | Alloy-400, Alloy-K500, Alloy-625, Alloy-718, Alloy-825, Alloy-20, Alloy-C276 |

| Exotic Alloys | Alloy-A286, Alloy-X750, Alloy-218, Alloy-254, SS-904L, XM-19 |

Dimensional Standards of Industrial Valves

| Valve Type | Size Range | Pressure Rating | End Connections | Standards |

|---|---|---|---|---|

| Butterfly Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Flanged, Wafer, Lug, Welded | DIN, ASTM, ASME, BS, International Standards |

| Ball Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Screwed, Flanged, Butt Weld, Socket Weld | DIN, ASTM, ASME, BS, International Standards |

| Gate Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Flanged, Welded, Threaded | DIN, ASTM, ASME, BS, International Standards |

| Globe Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Flanged, Butt Weld, Screwed | DIN, ASTM, ASME, BS, International Standards |

| Pinch Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Flanged, Threaded | DIN, ASTM, ASME, BS, International Standards |

| Diaphragm Valves | 1 ½” to 72” | DN 40 to DN 1800 | Custom Pressure Ratings | Flanged, Threaded, Welded | DIN, ASTM, ASME, BS, International Standards |

Types of Industrial Valves

Butterfly Valves

Butterfly Valves are quarter-turn rotary motion valves used to regulate flow in pipelines with a disc that rotates perpendicular to the flow direction. These valves offer excellent throttling capabilities, compact design, and quick operation, making them ideal for applications in industries such as oil & gas, water treatment, power plants, and chemical processing. Available in various sizes, pressure ratings, and material grades, Butterfly Valves ensure efficient flow control with minimal pressure drop.

Key Features:

-

Quarter-turn operation for quick opening and closing.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800).

-

Offered in various pressure ratings for different industrial applications.

-

Manufactured using high-quality materials such as stainless steel, carbon steel, and special alloys.

-

Complies with DIN, ASTM, ASME, BS, and international standards.

Ball Valves

Ball Valves are quarter-turn valves designed for precise flow control and shutoff applications. They feature a spherical closure unit that provides reliable sealing with minimal pressure drop. Known for their durability, ease of operation, and leak-proof performance, Ball Valves are widely used in industries such as oil & gas, chemical processing, water treatment, and power generation. These valves are available in a variety of materials, pressure ratings, and end connections to suit diverse industrial needs.

Key Features:

-

Quarter-turn operation for fast and efficient flow control.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800).

-

Low torque requirement for easy operation.

-

Manufactured in various materials, including stainless steel, carbon steel, and special alloys.

-

Designed to meet DIN, ASTM, ASME, BS, and other international standards.

Gate Valves

Gate Valves are linear motion valves designed to provide full flow or complete shutoff in pipelines. They feature a sliding gate mechanism that moves perpendicular to the flow direction, minimizing pressure drop and ensuring an efficient sealing performance. Commonly used in industries such as oil & gas, water treatment, power generation, and chemical processing, Gate Valves are ideal for applications requiring uninterrupted flow and minimal fluid resistance.

Key Features:

-

Designed for full open and full close operation, ensuring minimal pressure drop.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800).

-

Suitable for high-pressure and high-temperature applications.

-

Constructed from durable materials, including stainless steel, carbon steel, and alloy steel.

-

Complies with DIN, ASTM, ASME, BS, and other international standards.

Globe Valves

Globe Valves are designed to regulate flow in a pipeline by moving a disc or plug against the flow direction. These valves provide precise throttling control, making them ideal for applications where flow regulation and pressure control are required. Used in industries such as oil & gas, power generation, chemical processing, and water treatment, Globe Valves ensure reliable performance in high-pressure and high-temperature environments.

Key Features:

-

Designed for precise flow regulation and throttling applications.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800).

-

Suitable for high-pressure and high-temperature environments.

-

Constructed from high-quality materials, including stainless steel, carbon steel, and alloy steel.

-

Complies with DIN, ASTM, ASME, BS, and other international standards.

Pinch Valves

Pinch Valves are flexible and reliable flow control valves designed for handling slurries, abrasives, and corrosive media. These valves utilize a rubber sleeve that is pinched to control the flow, providing a full bore passage when open and a tight shut-off when closed. Pinch Valves are widely used in industries such as mining, wastewater treatment, food processing, pharmaceuticals, and chemical processing due to their ability to handle viscous and particulate-laden fluids.

Key Features:

-

Ideal for handling abrasive, corrosive, and slurry-based media.

-

Full bore, unobstructed flow passage ensures minimal pressure drop.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800).

-

Low maintenance design with replaceable rubber sleeves.

-

Manufactured in compliance with DIN, ASTM, ASME, BS, and other international standards.

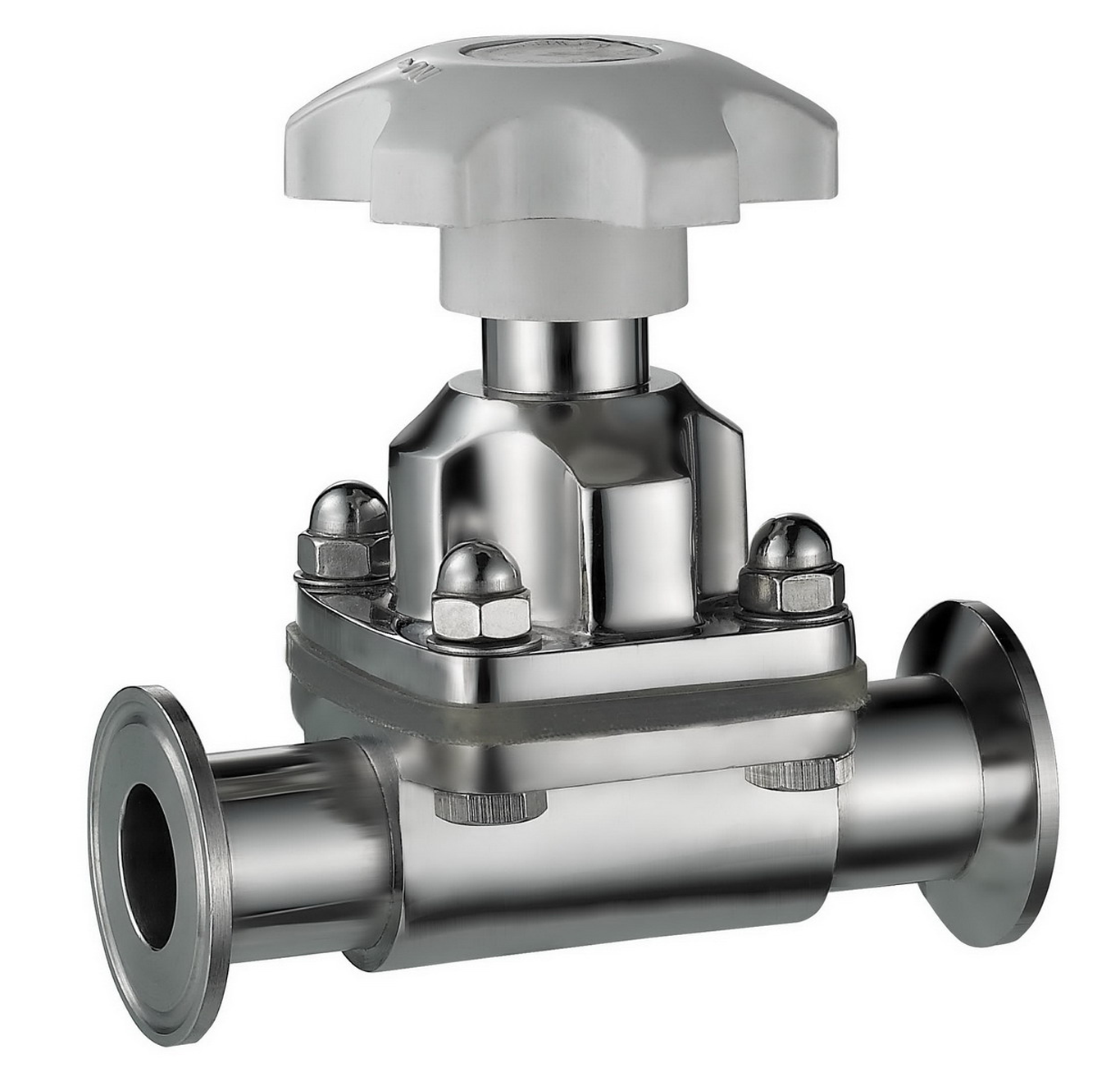

Diaphragm Valves

Diaphragm Valves are precision-engineered flow control valves designed for handling corrosive, viscous, and particulate-laden fluids. These valves feature a flexible diaphragm that isolates the process media from the valve body, ensuring leak-proof performance. Widely used in industries such as pharmaceuticals, water treatment, food & beverage, and chemical processing, Diaphragm Valves provide excellent sealing, easy maintenance, and long service life.

Key Features:

-

Ideal for handling corrosive and hygienic media with minimal contamination risk.

-

Full isolation of the process fluid from the valve body for superior leak prevention.

-

Available in sizes ranging from 1 ½” to 72” (DN 40 to DN 1800) with custom options.

-

Low-maintenance design with easily replaceable diaphragms for extended service life.

-

Manufactured in compliance with DIN, ASTM, ASME, BS, and other international standards.