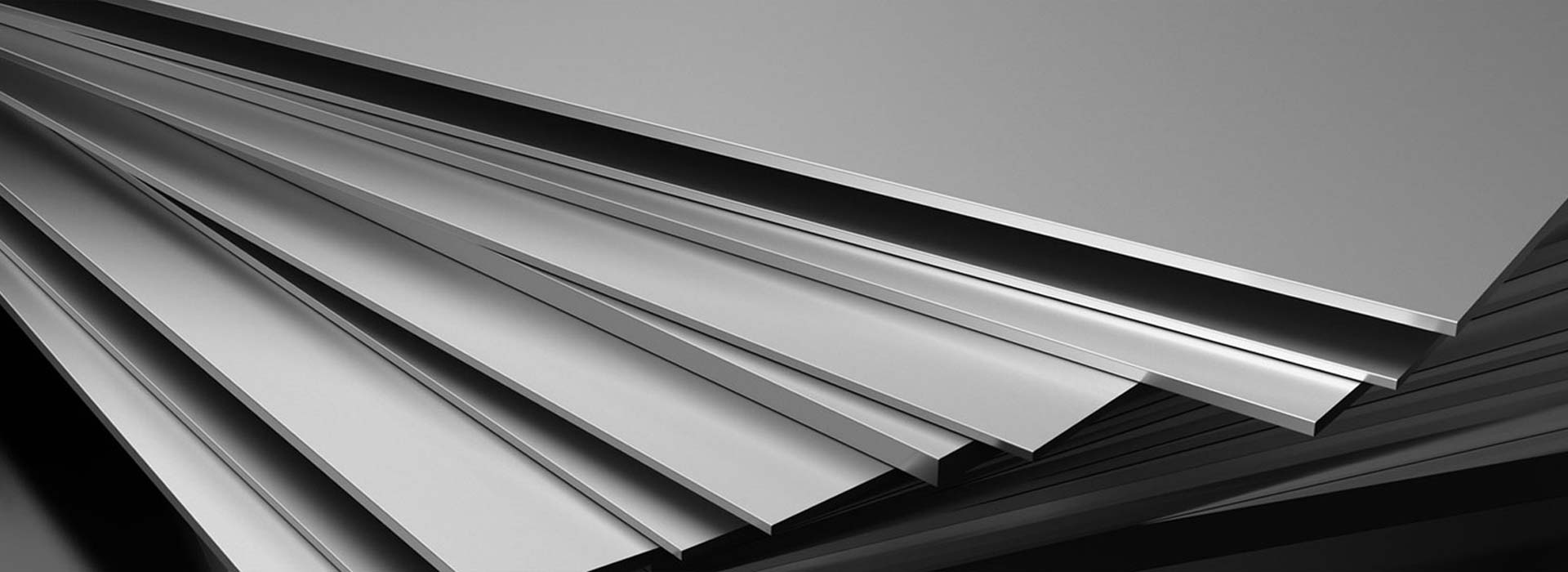

Sheet & Plate

Rivulet Industries LLP. is a trusted Manufacturer and Exporter of high-quality Sheets & Plates, engineered to meet the highest industry standards. Headquartered in Mumbai, India, we specialize in producing precision-engineered sheets and plates that offer exceptional strength, durability, and performance for a wide range of industrial applications.

Our extensive inventory includes Hot Rolled (HR), Cold Rolled (CR), Chequered, and Perforated Sheets & Plates, available in various grades, sizes, thicknesses, and specifications to suit diverse industrial needs. Whether you require Stainless Steel Sheets, Alloy Steel Plates, Duplex Steel Sheets, Nickel Alloy Plates, or Custom-Cut Profiles, we offer solutions that meet international quality standards, ensuring high performance under extreme conditions.

Manufactured using premium-quality materials, including Duplex Steel (2205, 2304, 329), Super Duplex Steel (2507/F53, 2507/F55, 255), Nickel Alloys (400, K500, 625, 718, 825, 20, C276), and Exotic Alloys (A286, X750, 218, 254, 904L, XM-19), our sheets and plates are designed for superior corrosion resistance, high tensile strength, and excellent mechanical properties. Each product undergoes strict quality control and non-destructive testing (NDT) to ensure precision, reliability, and longevity.

Designed for critical industrial applications, our sheets and plates support industries such as Oil & Gas, Construction, Chemical Processing, Power Generation, Aerospace, Automotive, Shipbuilding, and Heavy Engineering. Whether used for structural components, fabrication, heat exchangers, pressure vessels, or decorative applications, our products offer superior durability and performance.

At Rivulet Industries LLP., we also provide customization options in terms of dimensions, finishes (Matte, Mirror, Satin, Brushed), and material grades to meet specific project requirements. Our commitment to innovation, quality, and excellence ensures that our sheets and plates contribute to enhanced efficiency, reduced maintenance costs, and long-term reliability in industrial applications worldwide.

Available Grades of Sheets & Plates

| Alloy Type | Available Grades |

|---|---|

| Duplex Steel | Alloy-2205, Alloy-2304, Alloy-329 |

| Super Duplex Steel | Alloy-2507 / F53, Alloy-2507 / F55, Alloy-255 |

| Nickel Alloys | Alloy-400, Alloy-K500, Alloy-625, Alloy-718, Alloy-825, Alloy-20, Alloy-C276 |

| Exotic Alloys | Alloy-A286, Alloy-X750, Alloy-218, Alloy-254, SS-904L, XM-19 |

Dimensional Standards of Sheets & Plates

| Type | Thickness Range | Available Forms | Hardness Options | Standards |

|---|---|---|---|---|

| Sheet | 0.008" to 0.0125" | Coils, Foils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) | Soft, Hard, Half Hard, Quarter Hard, Spring Hard | ASTM, ASME, API |

| Plate | 0.0125" to 5.00" | Coils, Foils, Rolls, Strip, Flats, Blank (Circle), Ring (Flange) | Soft, Hard, Half Hard, Quarter Hard, Spring Hard | ASTM, ASME, API |

Types of Sheets & Plates

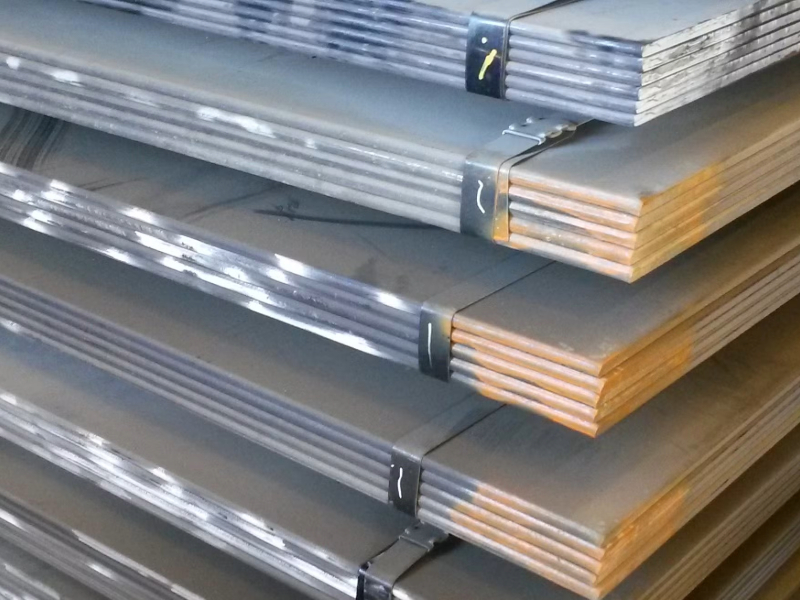

Hot Rolled Sheet & Plate

Hot Rolled Sheets & Plates are manufactured at high temperatures, making them easier to form, shape, and fabricate. These products are known for their superior strength, weldability, and cost-effectiveness. While Hot Rolled Sheets have a thinner profile and are used in lighter applications, Hot Rolled Plates are thicker and designed for structural and heavy-duty applications. Both are widely used in construction, automotive, shipbuilding, pressure vessels, and general fabrication industries.

Key Features:

-

Manufactured at high temperatures, ensuring excellent workability and ease of fabrication.

-

Hot Rolled Sheets are thinner and used in lightweight applications, while Hot Rolled Plates are thicker and suitable for heavy-duty applications.

-

Available in a variety of materials, including carbon steel, stainless steel, and alloy steel.

-

Good mechanical strength, weldability, and durability for structural applications.

-

Used in industries such as construction, automotive, shipbuilding, pressure vessels, and general engineering.

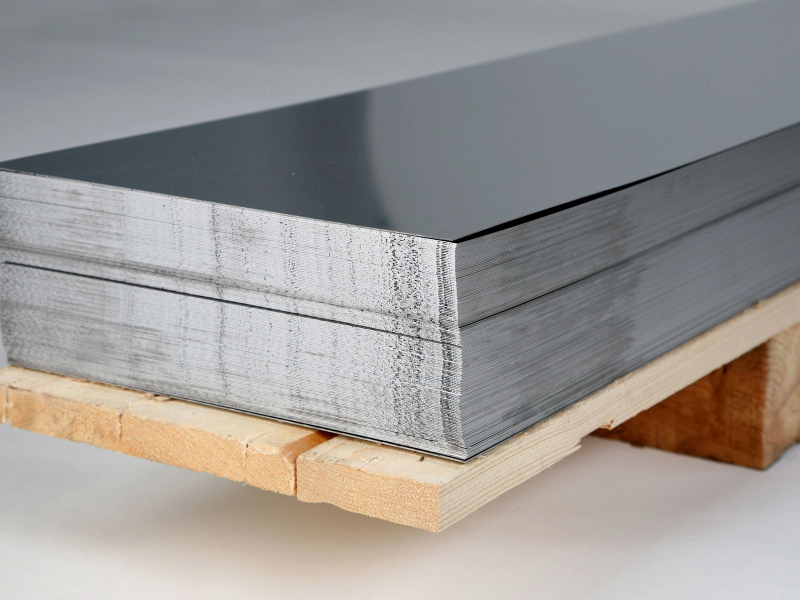

Cold Rolled Sheet & Plate

Cold Rolled Sheets & Plates are processed at room temperature after hot rolling to achieve a smooth surface finish, precise dimensions, and enhanced mechanical properties. These products offer higher strength, improved tolerances, and superior surface quality compared to hot rolled materials. While Cold Rolled Sheets are thinner and used in lightweight applications, Cold Rolled Plates are thicker and designed for structural and high-precision applications. They are widely used in industries such as automotive, aerospace, home appliances, and precision engineering.

Key Features:

-

Processed at room temperature for superior surface finish and dimensional accuracy.

-

Higher strength and tighter tolerances compared to hot rolled sheets and plates.

-

Available in various materials including carbon steel, stainless steel, and alloy steel.

-

Ideal for industries requiring precision, such as automotive, aerospace, and home appliances.

-

Excellent for applications requiring smooth, clean, and uniform surfaces.

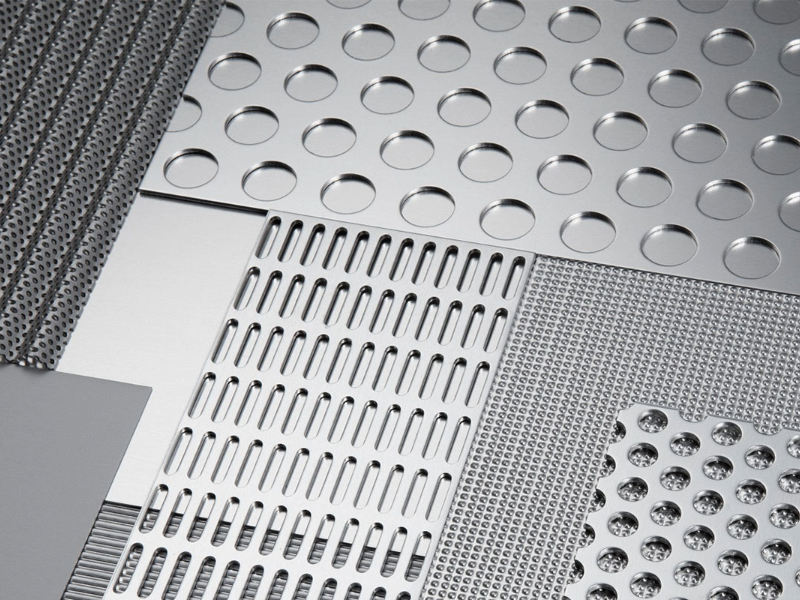

Perforated Sheet

Perforated Sheets are metal sheets that have been punched, stamped, or laser-cut with a variety of hole patterns, such as round, square, slotted, or decorative shapes. These sheets offer excellent ventilation, filtration, and aesthetic appeal, making them ideal for both industrial and architectural applications. They are widely used in construction, automotive, food processing, acoustics, and decorative facades.

Key Features:

-

Available in various hole shapes and sizes, including round, square, and slotted patterns.

-

Enhances ventilation, sound absorption, and filtration efficiency.

-

Manufactured from stainless steel, aluminum, carbon steel, and other alloys.

-

Widely used in construction, architectural facades, industrial machinery, and acoustics.

-

Customizable patterns and dimensions to meet specific design and functional requirements.

Wear Resistant Plate

Wear Resistant Plates are high-strength steel plates designed to withstand extreme wear and abrasion. Engineered with enhanced hardness and toughness, these plates are widely used in industries such as mining, construction, cement, and material handling. They provide superior resistance against impact, friction, and high-stress conditions, ensuring longer service life and reduced maintenance costs.

Key Features:

-

Exceptional resistance to wear, impact, and abrasion, increasing durability in harsh environments.

-

Available in various hardness levels, including AR400, AR500, and other customized grades.

-

Manufactured from premium alloy steel with superior toughness and weldability.

-

Ideal for industries such as mining, earthmoving, cement production, and material handling.

-

Available in various thicknesses and dimensions to meet project-specific requirements.